Many companies are now willing to use robots to replace labor, especially in some mass-production factories and injection molding factories. In the past, they used to manually take out products from injection molding machines. Following the various innovations behind, people wondered if it was possible. Develop a mechanical arm that can replace labor to take out the product from the injection molding machine, so that there is no need for so much labor. Now it is so difficult to recruit labor. Human cost and power must be considered. Then the robot on the injection molding machine is developed to What are the advantages of the end related to artificial? Injection manipulator

The first major pain point: the recruitment problem

In fact, the "price" of workers is now very clear. "The new generation of workers has at least nine years of compulsory education and is an only child. They would rather go to work in an office building for 3,000 yuan than to go to the factory with a salary of 4,000 yuan." "In addition, social security and average salary have increased year-on-year, but now they can’t go to work. Lathe robots are short of people.” The emergence of manipulators and robots has handled this situation well.

The second point is the development trend of the society

From a long-term benefit point of view, the emergence of manipulators, robots, and automation has promoted the development of society. As far as Chinese production is concerned, how to make ordinary workers' operations—or directly a certain repetitive action—do faster Being more accurate is a perennial proposition of production supervisors, and it is also a major "advantage" of the rise of Chinese production in the past internationally. The research energy down to the countdown was transferred to the machine.

The third point is an issue that companies are most concerned about, interest. Manipulator replacement can save production costs

"In the past, it was all labor and a crowd of people." Basically, an injection molding machine is equipped with a worker. Sometimes in order to catch up work, it will take two shifts or even three shifts. Workers keep working overtime and shifting. However, with the increase in labor costs, injection molding machine manipulators seem to be less expensive. After the introduction of the new version of the labor law in 2015, the basic salary of workers in the Pearl River Delta has risen to 2030, plus the normal overtime pay, which has basically risen to the present level. 4000 to 4500 yuan per month, together, not even the five insurances and one housing fund.

"Of course, in the process of operation, the absolute speed of human movement is faster than that of the manipulator of the injection molding machine, but human movement cannot be sustained for a long time, and it is not stable. Human nature has an uncontrollable side and cannot work for 24 hours." A worker counted, The cost for a year is about 50,000-70,000 yuan, which is now the price of one or two manipulators, and the useful life of the manipulator is about 8-10 years, that is to say, the remaining years are It's free to use, and when you calculate it, you can save hundreds of thousands or even millions of production costs for your company. Injection manipulator

The fourth point is that safety is increasing, and work-related injuries are basically gone

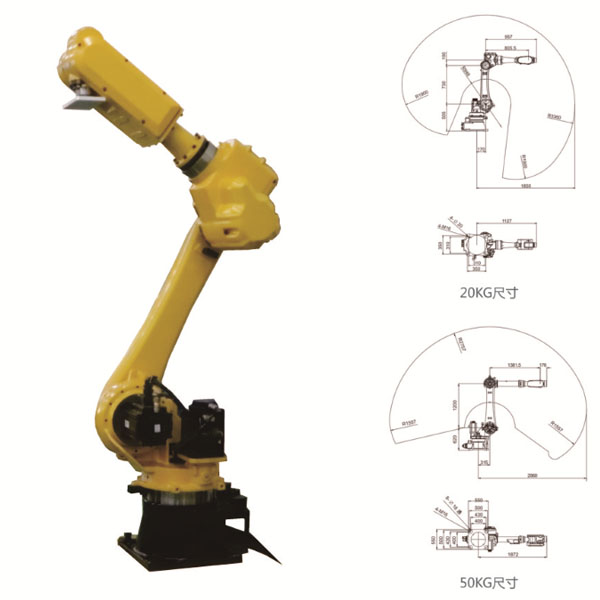

The occurrence of work-related accidents is a bad news for both the company and the employees. Now, the manipulator is a multifunctional manipulator that can realize automatic control and repeatable programming, and has three or more than three. The freely programmable motion axis seems to be a simplified combination of human upper limbs. Those workstations with high repeatability and harsh environment, such as oil injection, polishing, etc., are the first places where robots enter. In addition to hands, there are "feet". This is the international work of general workers: "Porters are the hardest. Many people leave after a week. The mobility of workers is great. The workers in the past are better, but the young workers now sometimes can't stand it for a day." This kind of work It also happens in the conceptually fashionable e-commerce warehouse. Chen Hongbo once made statistics. During Double Eleven, workers in an e-commerce logistics warehouse had to walk about 50 to 70 kilometers a day with boxes, exceeding the interval between two marathons.

I believe that if you use manual labor, all of the problems we will encounter, but if you use an injection molding manipulator, you can handle the problem well. If you find a manipulator, the automation solution should go to our Keshide automation machinery manufacturer. The after-sales system and the high cost performance are all worthy of you.